Things You Should Know About Ball Screw HBN

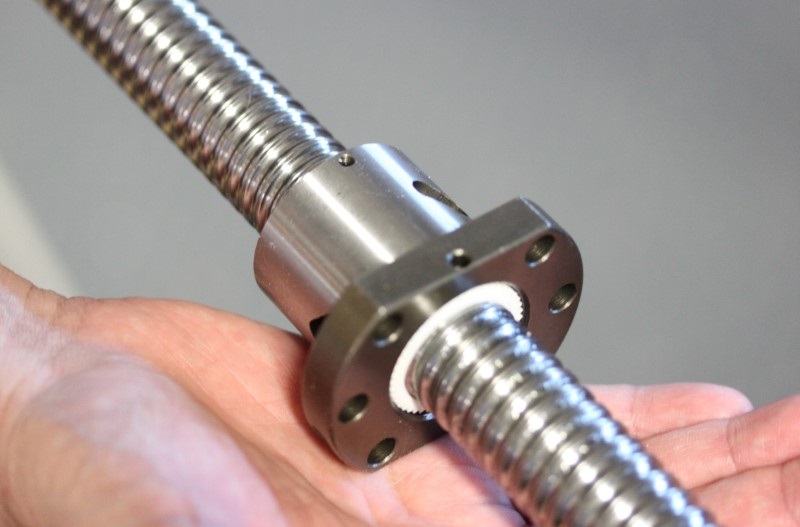

Ball screw HBN (บอลสกรู HBN, which is the term in Thai) is a mechanical device that can convert rotary motion into linear motion with an efficiency of up to 98%. The ball screw’s recirculating mechanism makes this possible by using ball bearings to roll along the screw shaft and the nut.

The internal friction of a ball screw is kept to a minimum so that it can either apply or resist considerable thrust pressures.

Because of their excellent efficiency, load capacity, and positioning accuracy, ball bearings reduce or eliminate friction between the nut and the screw.

Examples Of Using Ball Screws

High-performance machine tools and other applications that require exceptional precision and accuracy, such as medical devices, are ideal places for ball screws.

Ball Screws Are Commonly Used When The Following Factors Are Essential:

- Extremely Effective

- Functioning Effortlessly

- Operating Accurately

- Moving Continuously

- Moving Rapidly

The Following Are Some Examples Of Where Ball Screws Are Used:

- Ball screws can be utilized in place of conventional hydraulic systems in electric automobiles.

- Ball screws are used to adjust the pitch and angular position of the blades on wind turbines.

- In solar panel tracking systems, ball screws provide motion on two or three axes.

- Ball screws are used to operate gates at hydroelectric power plants.

- Motorized inspection tables—a ball screw within the mechanism aids in setting the tables in the ideal position for a specific task.

- Ball screws are a type of lithography equipment used in step photolithography machines, which are used to create small integrated circuits.

- Ball screws are commonly utilized in automatic steering systems for automobiles.

Advantages Of Ball-Screw

The mechanical efficiency of ball screws is exceptionally high. A ball screw can convert around 90% of the rotational motion of an application into linear motion, according to the statistics. Lead screws, on the other hand, are only about 20% to 25% efficient mechanically. These results indicate that ball screws are three to four times more efficient than lead screws at transforming mechanical energy.

Ball screws have less friction because, well, they use balls. This is because of their built-in nut for revolving ball bearings. By minimizing friction and allowing the screw to glide easily, ball bearings extend the life of a ball screw.

Conclusion

Ball screws offer advantages not shared by other industrial motion screws, such as roller screws or acme screws.